GALILEI CIRCLE OF FRIENDS – Interview with Lorenzo Maffioli

This week we have the pleasure to host on our “Galilei Circle of Friends” an old friend of our Institute, Lorenzo Maffioli. His story is unique in the managerial panorama between our two countries. He has lived in different “Chinas”, Chongqing and Shanghai, where he performed at the highest business level. He can count on a long and faceted experience on the ground, and surely enriched our interviews with his vision on China. Enjoy it!

PART 1 – Mister Maffioli’s Personal Relationship with China

How did your relationship with China start? Did it happen by chance, motivated by business reasons or for pleasure?

It was the opportunity that changed my life.

After graduating in management engineering at the Polytechnic of Milan, I joined Iveco in 1995. My first “professional school” was the Iveco factory in Brescia, where I started in the press and bodywork workshop and from where, after some internal promotions, I left in 2002 holding the role of production manager of the subsidiary Astra Veicoli Industriali of Piacenza. At that time it was normal for a young production manager to gain experience at a smaller company plant.

Two years later, in search of greater managerial independence, I decided to leave the large company to gain my first experiences in the reality of medium-sized Italian companies, the backbone of the Italian industrial sector. After a brief experience in Bolzoni Auramo, I arrived in Itema, as production and purchasing manager of the Italian headquarter.

China entered my life in February 2007 when Iveco, which was about to set up, together with SAIC (Shanghai Automotive Industry) and Chongqing Heavy Vehicles, its second joint venture in China, decided to seek outside the company as the production director of the forthcoming JV. They examined the possible candidates of those who had already had experience in Iveco. I accepted the job, returned to Iveco, made two preparatory trips between April and June, and then moved to Chongqing in July 2007.

How has your relationship with China evolved over time?

After finishing my assignment in Chongqing in 2011, I wanted to stay in China. Unfortunately, a dramatic event, the serious illness of a colleague and friend whom I highly esteemed, brought me back to Italy as new director of the Iveco factory in Brescia. It was the plant where I started as a recent graduate and the largest Iveco plant in the world. Becoming the director was probably the most important professional honor I have ever achieved.

However, I carried within me the fascination of the speed of change, of the spirit of evolution, of Chinese industry. I saw myself as a manager who had developed a good curriculum in operations; I felt I was lucky because I was doing the job I wanted: after the experience in Chongqing, I was aware that at an international level, China was the place that offered the best opportunities and the greatest satisfactions in my professional sector.

The opportunity to return to China came in 2012, when Itema offered me to come to Shanghai, as managing director of the Chinese branch, a position that allowed me to add sales and marketing to the operations experience. From 2012 to today, and I still foresee a few years in the future, my life has been in Shanghai.

Lorenzo Maffioli together with Qi Lancheng at SIH New Site Jiangbei, Chongqing, 2009

What has your personal and work experience taught you in this beautiful country?

I think it taught me to study and to interpret an environment in continuous and fast change. What happens in China in five years, in other parts of the world requires twenty or more.

Whether you are talking about customers, technologies, suppliers or, most important of all, the people who are our collaborators, in China you learn that they are dynamic, that they are evolving, that they aspire to something better and that, therefore, if you do not want to be left behind, if you want to seize the best opportunities for your business, you have to document yourself and anticipate these changes.

Soon enough, I learned not to generalize, to grasp that, even if part of the same great nation, the habits, needs, and consumption of a Chinese from Heilongjiang are different from those of a Chinese from Guangxi, for example.

For me, as I believe for many foreign managers residing in China, not generalizing recently evolves in the ability to objectively evaluate the results of the political and economic system where I operate, its ability to generate well-being for the people who live in it and, in general, to build what in China is called “the harmony of society”.

The most important personal experience that China is giving me is therefore the ability not to accept a priori the superiority of one political system over another, with the consequent awareness and balance in evaluating something different from us that this entails.

Lorenzo Maffioli together with Sergio Marchionne, former CEO of Fiat-Chrysler Automobile at the SIH Jiangbei Site side members workshop in 2010

PART 2 – Business Experience in Chongqing and Shanghai

How has China changed compared to your early years from a business point of view in your specific sector? What are the differences that struck you most positively and negatively?

A lot has really changed. I would mention, just as examples, two aspects: the availability of professional technical skills and the quality of suppliers and components.

In 2007, one of the critical success factors that I discovered crucial upon arriving in China was how to find the person with at least minimal technical skills for a given position, how to persuade them to move from other parts of China to Chongqing, or, alternatively, with whom which training plan supported by the parent company in Italy to raise a local technician to the necessary competence level.

Today, in Shanghai but also in many other parts of China, I believe a standard similar to the European one has been reached, the technical skills required are widely available in the job market, you just need to know how to be attractive. In some areas, the situation has even already reversed. Chinese technicians may have more advanced skills to pass on to colleagues in other countries where the company operates.

Still only in 2013, the premium price that Chinese customers recognized, in our reference market, for European components, guided my company to the transition, for our production in Shanghai, to the full application of a common platform strategy between production in Italy and production in China.

Today, the common platform strategy is still the guiding principle of our product offer, especially from the design point of view, but we are working on the evolution of this strategy with collaborations with leading Chinese mechanical companies, which in the meantime have reached the same level of quality and performance of European suppliers. For part of the components, in particular this occurs where the applications required by the Chinese market are more demanding in terms of performance and where the volumes of the Chinese market allow greater investments in R&D and process, it is not unusual to find more performing solutions and components than European equivalent.

I do not see anything that has worsened, let’s say that in my work China sometimes appears to me as a train that modernizes the locomotive, adds new wagons with greater comfort and services, but finds it difficult to unhook the old wagons from the train. Fast evolution emphasizes the aspects that do not evolve as anachronistic.

For example, I experienced the extraordinary evolution in the protection of brands, even on digital sales systems, where in a few years a culture was formed and a regulation was implemented, almost completely bridging the gap with the rest of the world. On the other hand, the maintenance, in parallel, of a still peculiar patent system, partly protective of local companies, not easy to access, therefore appears as a remnant of the past that I hope will soon be addressed.

A pic from the inauguration of the SIH Jiangbei Site, Chongqing

Tell us about your experience in Chongqing. What was your role and what are the main achievements?

I was the production manager of the JV, Saic-Iveco Hongyan. Being a complex JV, with three companies involved, in a sector classified as strategic, the organization had been codified at the time of the establishment of the JV. Iveco had primary responsibility for the Product Development, Production, Supply Chain, Quality functions, to be covered through nine managers assigned to the JV staff, Iveco employees partly foreign and partly Chinese. Iveco also had a technology, product and process transfer agreement in favor of the JV, for which a team of about 20 engineers and technicians also operated in Chongqing.

The JV received as a dowry Hongyan, a historical Chinese brand of heavy trucks, founded in 1965. I had to manage the Hongyan industrial park, located in Shuangqiao, about 80 km from Chongqing, while we were building the company’s new factory in the Jiangbei district. The project included the development and then the production in the new plant of a new range of heavy trucks, which took the commercial name of Genlyon, with Iveco design and technology, a revolution of the Hongyan product, especially for the cockpit part. In parallel, we managed the transition of the JV to a complete ERP system.

As a result, I mainly operated in the old plant for the first 12 months, in Shuangqiao we were producing about 20,000 trucks per year, and then moved to the new plant in late 2008, where my colleagues from the support team had worked, to manage the start of production.

The press department began production in January 2009, on March 12th 2009 the Genlyon was presented on the market with a launch event at the National Gymnasium in Beijing. On April 16th 2009 the new plant was inaugurated.

With its approximately 400,000 square meters of total area and approximately 180,000 square meters of covered area, it remains the largest project for a new factory and new production that I have helped to carry out. The organizational complexity was another challenge: in the transition phase between the two plants, in 2010, I was the director of an organization that included about 5,000 people. The Hongyan plant in Jiangbei, expected at the start of the project for 160 vehicles per day, in the spring of 2010 reached a production of 220.

In parallel with Saic-Iveco Hongyan, colleagues from Fiat Powertrain Technologies built the plant for the production of the engines. In the following years, Iveco chose to reduce its stake in the Chongqing vehicle JV while maintaining management of the engines JV. So today in Chongqing, 12 years after the inauguration of the plant, Iveco is mainly associated with engines and perhaps few remember that the vehicle plant was also built and brought up to speed by Iveco managers and technicians.

However, there are still many Genlyons at work in China with the “Iveco Technology” banner on the side: one of these, for example, was the protagonist in the video on the construction in record time of the extraordinary hospital in Wuhan in February 2020.

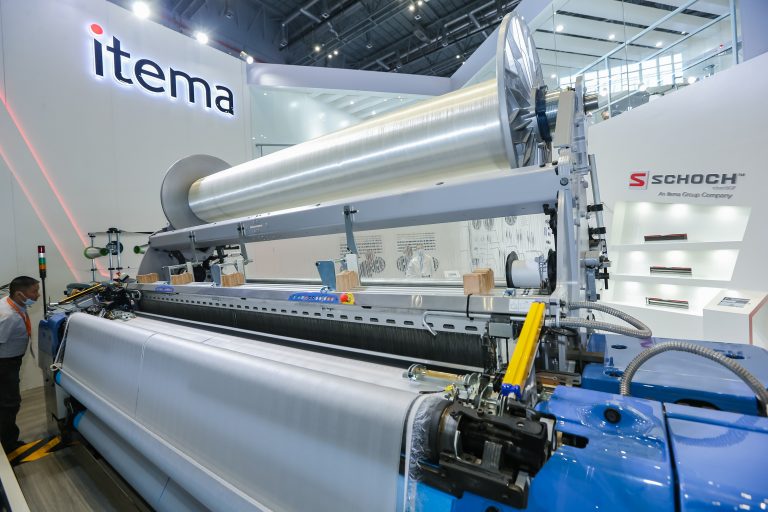

Itema machinery at the ITMA Asia Fair in Shanghai, NECC, 2021

What are the projects you are aiming for and future goals at ITEMA?

Itema is a world leader specializing in shuttleless automatic weaving machines, spare parts and related services. We design, manufacture and sell machines with three (gripper, air, projectile) of the four weft insertion technologies available: by choice, we have never produced machines with water insertion given the greater environmental impact of this technology.

Our customers are weaving companies and China accounts for around 50% of the world’s textile production. Due to the characteristics of the Chinese textile supply chain, in China we mainly sell rapier and projectile machines, intended for high-end weavers, who produce both for export and for the domestic market and operate in the most varied application segments, from silk to denim, from clothing to home furniture and the vast field of industrial technical fabrics. For rapier machines we have a share of about 20% of the Chinese market, while for projectile machines, which represent a niche, we are the only manufacturer in the world.

On a commercial level, we sold the first machines in China in 1981, we have a production plant in China since 2004, we are a local to local business from the beginning, we leverage the versatility and output quality of our machines, thanks to the specific innovation of our product, and we follow historical and new customers in their development which at the moment includes, in terms of main trends:

- the rebalancing between exports and the domestic market, where the relative weight of the domestic market is increasing for many of our customers, both in volume and in the quality of the product they have to make;

- the four guidelines of the Chinese textile sector, therefore new materials, sustainability, product upgrades and process digitization;

- investments in production sites abroad.

On an industrial level, we mainly work on new versions of our machines following three guidelines:

- functions to ensure better efficiency, therefore lower electricity consumption and less waste for the same fabric produced, with a view to improving the sustainability of our customers’ process;

- digitization;

- for the production we carry out in China, cooperation with leading Chinese companies in the textile machinery sector.

How has the pandemic affected your business and what strategies have you implemented to respond to the crisis?

In China, the most difficult moment was the second quarter of 2020, when our customers, mainly exporters, received order cancellations from the main export markets, Europe and the USA. As a result, investment in machinery also collapsed.

However, since the third quarter, and definitively since the fourth quarter of last year, we have seen a strong recovery that continues even now. 2021 will be the best year since the founding of Itema China both in terms of turnover and profitability. Although not yet supported by reliable data and certainly subject to volatility in the coming years, together with our customers we are experiencing an evolution in domestic consumption that exceeds expectations.

At the time of the crisis, the measures taken were many, let’s say that the most important common denominator was to transmit safety to collaborators and suppliers: we produce complex machines in thousands of variants and with an important content in terms of service, much more. disruptive for us is the loss of internal and external expertise that a few months of non-entry orders.

For our headquarters in China, for example, we signed an internal agreement that provided for the possibility for each employee to sign up or not, on a voluntary basis, a form of self-protection of the workplace on equal terms for at least 12 months in exchange. flexibility in working hours. 90% of the staff adhered to the agreement, which was then largely exceeded by the positive market trend in the last part of the year, but in mid-2020 it represented an important sign of continuity.

What are the main challenges you have encountered in your long experience as a successful manager in China? What are the positive surprises?

After 13 years of working in China, both in Chongqing and Shanghai, the main positive surprise is always the value that my collaborators recognize in coaching. The manager who tries to teach a new method, who shares his experience, here is able to read their satisfaction on people’s faces. There is a culture of respect for those who teach, a natural propensity to consider that if you teach me it means that you respect me, which in my experience has no equal elsewhere.

Another aspect, more recent: for about a year in Itema China we have embarked on a structured path of generational change of management, we try to build a team capable of covering the key positions of the branch in the next 10-15 years. Thanks to this project, I can now observe the growth of managerial independence between one generation and the next of my Chinese collaborators. I am surprised with satisfaction to discover the activities for which the directors of the previous generation who have recently retired would have asked me for various authorizations, mostly useless, have been completed independently by the directors in their thirties.

Worker at the end of Assembly Lane, SIH Jiangbei Site, Chongqing, 2009

PART 3 – Relationship with our Institute

What is your relationship with the Galilei Institute? Did you get to know the staff during your years in Chongqing and follow their activities?

Certainly. I have participated in various activities, both personally and professionally. In December 2010, Saic-Iveco Hongyan was also a sponsor of the photographic exhibition by Paolo Barone “Sicily – Fifty Images”, organized by the Galilei Institute.

Interview by Alberto Di Minin and Marco Bonaglia